To sign up to receive our emails, fill in the following fields and hit submit. Thanks, and welcome!

"*" indicates required fields

To sign up to receive our emails, fill in the following fields and hit submit. Thanks, and welcome!

"*" indicates required fields

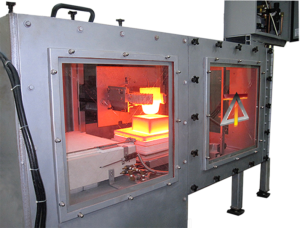

When looking to purchase a resistance-heated batch furnace, there are a number of factors to consider before making your final decision. Resistance-heated furnaces are electrical furnaces that use heat that is generated by conductors. These furnaces are commonly used in heat treatment, where materials need to be heated before they are melted, dried or pressure shaped. In this blog post, we will look at some key points to keep in mind when choosing a resistance-heated batch furnace specifically for glass melting applications.

From being able to efficiently manage temperature control to maintaining a safe furnace atmosphere, there are a number of aspects to consider when looking to purchase a batch furnace. In the following section, we will take a look at these points and why they are important.

Corrosion Resistance

Furnaces are frequently filled with highly corrosive fumes, especially glass melt furnaces, and therefore it is crucial that they are able to withstand them. Corrosion-resistant materials to look out for include high alumina ceramic, for temperatures up to 1700oC and cast zirconia for temperatures between 1800oC and 2000oC.

Control System

Furnaces can be designed with a range of control systems and this is something to consider before making a purchase. You need to be sure that the control system installed is sophisticated enough to meet your requirements.

Furnace control systems help to manage temperatures, heat delivery, air mixture and other important variables.

Facilitates Access During High Temperatures

Some processes require human intervention during the heat treating process, for example: during glass heating, it may be necessary to fine the glass. This would require stirring the glass or having gas bubbled into the melted glass. Additionally, the glass may need to be poured into the furnace. These actions will need to be made possible by the furnace having a top opening that is both heat resistant and prevents corrosive fumes from leaving the furnace chimney. The furnace will also need to have been designed to easily and safely load and unload the materials.

Protective Lining

Because some glasses contain hazardous materials, the protective lining of the furnace is an important aspect to consider. Some of these materials refer to glasses containing copious amounts of chlorine, fluorine or sodium, which can damage molydisilicide heating elements.

Furnaces need protective lining to separate the elements from the hot zone of the furnace to protect both product and the furnace itself.

Safe Access

If you are using a furnace for a process that requires human intervention part-way through, it is important to consider this when choosing a furnace for your lab. Similar to ‘access during high temperatures, the furnace must be designed to allow a safe way to access the glass during production. One example is a pneumatic door, as it allows quick access to crucibles and the heating chamber.

Supplier Experience

This almost goes without saying but you should look to buy a batch furnace from a supplier who has proven experience and positive reviews within the field. If you require a custom build or glass batch furnace with specific requirements, look for a supplier who can meet those needs instead of buying an off-the-shelf furnace that works for a range of standard applications.

If you are looking to purchase a resistance-heated furnace or would like more information about our products, please contact us today and our team will be happy to assist you.

Deltech is a family owned small business incorporated in 1968. Members of the Stevenson family are part of the day-to-day operations in management, sales, engineering, and production.

Address:

Deltech Inc.

1007 East 75th Avenue, Unit E

Denver, CO 80229-6442 U.S.A.

© Copyright 1998 -2024 Deltech Furnaces

PRIVACY POLICY | SITE REQUIREMENTS | SITE MAP | INFO FOR EMPLOYEES

Our ongoing accessibility effort works towards being in line with the Web Content Accessibility Guidelines (WCAG) version 2.2, levels A and AA criteria. These guidelines not only help make web content accessible to users with sensory, cognitive, and mobility disabilities but ultimately to all users, regardless of ability.

This website is just part of a meaningful change in making all State of Colorado services inclusive and accessible. We welcome comments on how to improve this website’s accessibility for users with disabilities and for requests for accommodations to any State of Colorado services.