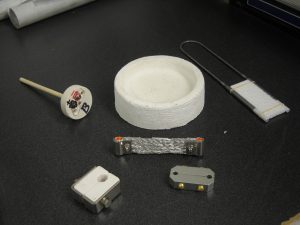

Tips on avoiding furnace down crises and the often related expenses… The first is keep a few spares for critical consumable components on hand. What are these “critical consumables”?

- Heating elements

- Element connectors

- Thermocouples

- Hearth Plates

Heating elements

When I replace the water filter in my refrigerator, I reset a counter that indicates via a light that so many gallons have passed through the filter and it’s time to reorder. When the light turns from amber to red I know it’s time to change out the filter. Heating elements don’t come with any such early warning system. An element that’s been in use for a good long time may just suddenly fail. Or you reach into the furnace with your tongs to pull out a crucible, and you hit an element causing a mechanical break. Or you apply too much torque to the connector when you replace an element resulting in stress fractures and rapid failure. Or your element connector gets old and tired and causes arcing, in turn destroying one or more elements.

Deltech Furnaces keeps many sizes of heating elements in stock for shipment within one business day, but some sizes and types are special order and can take up to six weeks for manufacture. It is commonly believed that element manufacturers keep many sizes in stock, but this is not the case.

Action plan: Keep at least two spare elements on hand to minimize your risk of down time. Contact us for information.

Element connectors

Focusing on the accessories for molydisilicide heating elements, your furnace may feature buss bars or some combination of holders and braids, depending upon the element size. If these are not installed correctly, they may allow arcing which can destroy elements. (See our element tutorials for more information.) Buss bars can become burned and pitted over time, again resulting in a poor connection and arcing. Braids fray and suffer from heat damage.

Action plan: Inspect the element connectors and braids frequently. Watch for signs of arcing when power is applied to the elements. Contact us for information and pricing on replacement parts.

Thermocouples

Thermocouples age over time, causing them to read low. This can result in the actual furnace temperature being much higher than that indicated, creating the potential for considerable damage, even the destruction, of the furnace elements and lining. Thermocouples should be replaced at least once per year.

Action plan: Add thermocouple replacement to your maintenance schedule. Periodically check their accuracy by comparing the readout with that from an independent thermocouple. Portable versions are quite inexpensive. Consider keeping spares on hand; contact Deltech.

Hearth Plates

Hearth plates and spill traps provide a hard ceramic surface for the placement of your workpiece. Suppose you have a crucible of glass in place, and the glass bubbles out onto the spill trap. The good news is that the trap has contained the spill; the bad news is that the plate is now ruined.

Action plan: Keep a spare setter plate on hand. Contact us for availability and pricing; we keep most sizes in stock.

Tip #2: Don’t forget about your furnace insulation. Over time it loses its thermal properties and you might find yourself with a furnace that can’t reach the desired temperature.

Action plan: Inspect your furnace insulation on a regular basis for signs of excessive cracking (think “fissures”), sagging, or separation. Also, when the furnace is running look for signs that light is escaping from the wrong places. It might be time to repair or replace a part, or g

Furnace roof hot face insulation featuring sagging and separation

et a rebuild on the schedule. If you are in doubt, send some digital pictures to Deltech for evaluation.