To sign up to receive our emails, fill in the following fields and hit submit. Thanks, and welcome!

"*" indicates required fields

To sign up to receive our emails, fill in the following fields and hit submit. Thanks, and welcome!

"*" indicates required fields

Deltech supplies 3 different types of benchtop furnace, all of which are simple to use and maintain and have features which can be used for various kinds of thermal processing. This can be for both research and product manufacturing purposes. The versatility of a benchtop furnace means that the same furnace can be used despite products and processes changing over time. This blog will outline 3 types of benchtop furnaces and their uses.

Front Load Benchtop Furnace

Deltech’s front load benchtop furnace has the lowest initial cost out of the three outlined in this article and requires the least amount of lab space. Because the door motion is manual, this benchtop furnace requires the lowest maintenance costs.

Deltech front load furnaces can be used for temperatures from 1500-1800°C and can be used in air and inert atmospheres. Deltech offers standard sizes as well as custom configurations for a benchtop furnace.

This benchtop furnace is produced with the highest quality materials available and the doors can be manual or power operated. The front load furnace promotes operator safety by guaranteeing cool exteriors, with a convection cooling design which eliminates the requirement for cooling fans.

Ceramic linings are used for corrosion resistance, making this benchtop furnace well-suited to glass melting applications.

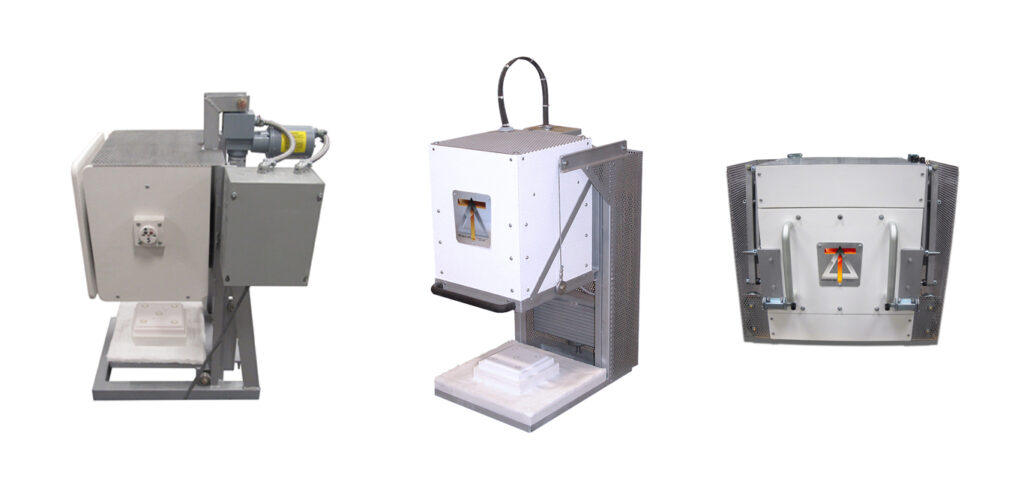

Bottom Load Benchtop Furnace

The bottom load benchtop furnace, also known as an elevator furnace, offers an increased uniformity over front load furnaces. This is because the bottom load is heated on four sides, rather than three. The load platform can be lowered at high temperatures to rapidly remove product for quenching. This benchtop furnace also has an electro-mechanical or pneumatic load platform, meaning the operator’s hands remain free for loading.

Bottom load furnaces from Deltech can operate at up to 1800°C. The furnace body stays stationary as the load platform is raised into the correct position. This benchtop furnace utilizes silicon carbide or molydisilicide heating elements, depending upon the maximum operating temperatures.

Top Hat Benchtop Furnace

A top hat benchtop furnace also provides a uniform heating due to its four-sided heating. It has a fixed loading platform which means it is excellent for maintaining the stability of multiple stacks of small parts supported by kiln furniture or fixtures. Additionally, the electro-mechanical or pneumatic shell lifts means that the operators hands are free for loading. Top hat furnaces are well-suited to processes in which stability is critical, such as in gradient glass manufacture. This benchtop furnace uses linings of superb quality which allows for rapid heating and cooling.

Whatever benchtop furnace you require, Deltech can offer expertise in manufacturing furnaces which fulfill your specific process requirements. This can be a modified standard benchtop furnace or a custom system. Each type of benchtop furnace has advantages and disadvantages and the correct selection is largely dependent on individual requirements. To speak to an expert for advice, contact us today.

Deltech is a family owned small business incorporated in 1968. Members of the Stevenson family are part of the day-to-day operations in management, sales, engineering, and production.

Address:

Deltech Inc.

1007 East 75th Avenue, Unit E

Denver, CO 80229-6442 U.S.A.

© Copyright 1998 -2024 Deltech Furnaces

PRIVACY POLICY | SITE REQUIREMENTS | SITE MAP | INFO FOR EMPLOYEES

Our ongoing accessibility effort works towards being in line with the Web Content Accessibility Guidelines (WCAG) version 2.2, levels A and AA criteria. These guidelines not only help make web content accessible to users with sensory, cognitive, and mobility disabilities but ultimately to all users, regardless of ability.

This website is just part of a meaningful change in making all State of Colorado services inclusive and accessible. We welcome comments on how to improve this website’s accessibility for users with disabilities and for requests for accommodations to any State of Colorado services.