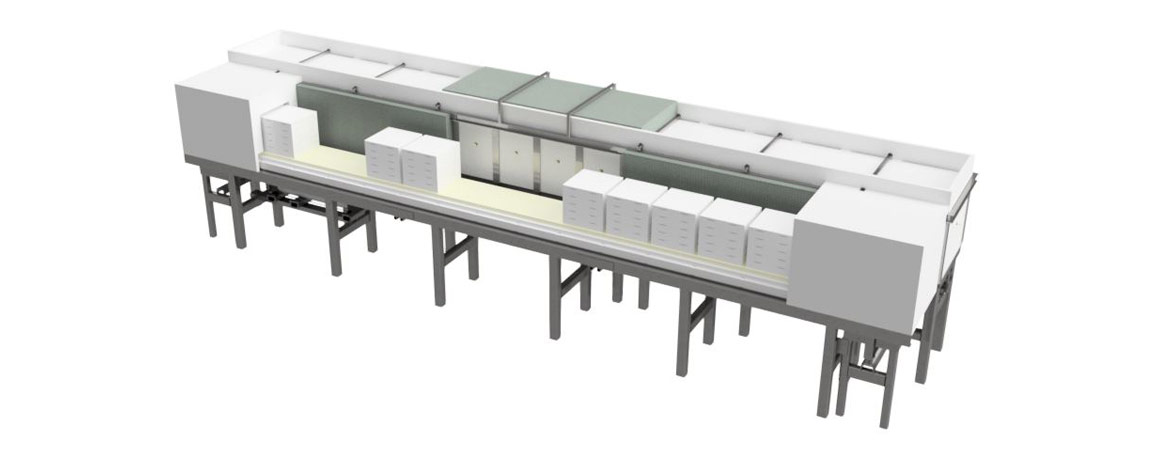

Changing from electric tunnel kilns to gas-fired furnaces can result in significant changes in product outcomes. A custom Deltech tunnel kiln offers a great way to scale up while duplicating the conditions in resistance-heated batch furnaces. Depending on your process parameters, a tunnel kiln might be preferable to a production-size ‘top hat’, bottom loader, or front load furnace. The good news is that a tunnel kiln will maintain the rapid heating and cooling and exceptional temperature uniformity characteristic of Deltech non-continuous furnaces. Check out the list below of many optional features available for your custom-designed and custom-built tunnel kiln.

To sign up to receive our emails, fill in the following fields and hit submit. Thanks, and welcome!

"*" indicates required fields