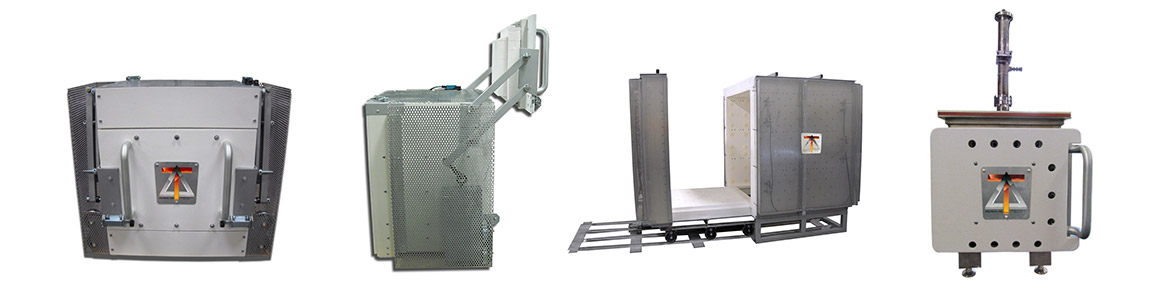

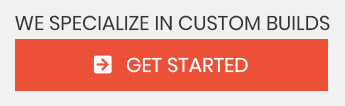

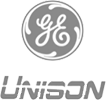

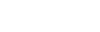

Front loading furnaces are suitable for various applications at a range of temperatures and are considered general-purpose furnaces. They are commonly used for heating treating and annealing, ceramics and powdered metal and sintering. Available in both benchtop and production sizes and for operation in air and inert atmospheres, front loading furnaces and kilns are ideal for operators requiring some flexibility that other furnaces do not offer. Front loading furnaces are available with temperatures from 1500 -1800 degrees Celsius and can be manufactured in standard sizes and custom configurations.

Does your process require an accelerated ramp rate? Consider our “fast fire” option, available for both benchtop and production scale front load furnaces. Ramp rates as high as 1000 degrees Celsius per hour can be attained, depending on the workspace size of the furnace.

Does your application require a furnace with unique features? If you require a custom-designed furnace or some additional features, Deltech can provide a solution a custom design is our specialty. To start off the process, we will discuss your process requirements and work with you to develop a solution grounded in broad engineering knowledge and considerable experience, making sure you have the equipment that is just right for you.

Customer Comments

“Good customer service and robust furnaces”

Deltech Furnaces Customer