To sign up to receive our emails, fill in the following fields and hit submit. Thanks, and welcome!

"*" indicates required fields

To sign up to receive our emails, fill in the following fields and hit submit. Thanks, and welcome!

"*" indicates required fields

Tunnel kilns offer many advantages for the efficient firing of large quantities of products. Here we look at the difference between intermittent and tunnel kilns and why tunnel kilns are favored for high-throughput applications.

Kilns can be broadly divided into intermittent kilns (also known as batch or shuttle kilns) and tunnel kilns (also known as continuous kilns). In the most basic sense, both intermittent and tunnel kilns are insulated boxes with controlled internal temperatures. However, different mechanisms of operation mean that there are significant differences between the capabilities of the two.

Intermittent kilns work in batches: the kiln is charged (filled), it heats up to firing temperature (usually in a carefully controlled manner), this temperature is maintained for a period, and then the kiln cools down (once again in a controlled manner). Because intermittent kilns fire one batch of products at a time, they’re typically used for small production volumes or intermittent use. This means that intermittent kilns are well-suited to applications such as artisanal pottery, where they can be easily reprogrammed to suit the firing requirements of specific products.

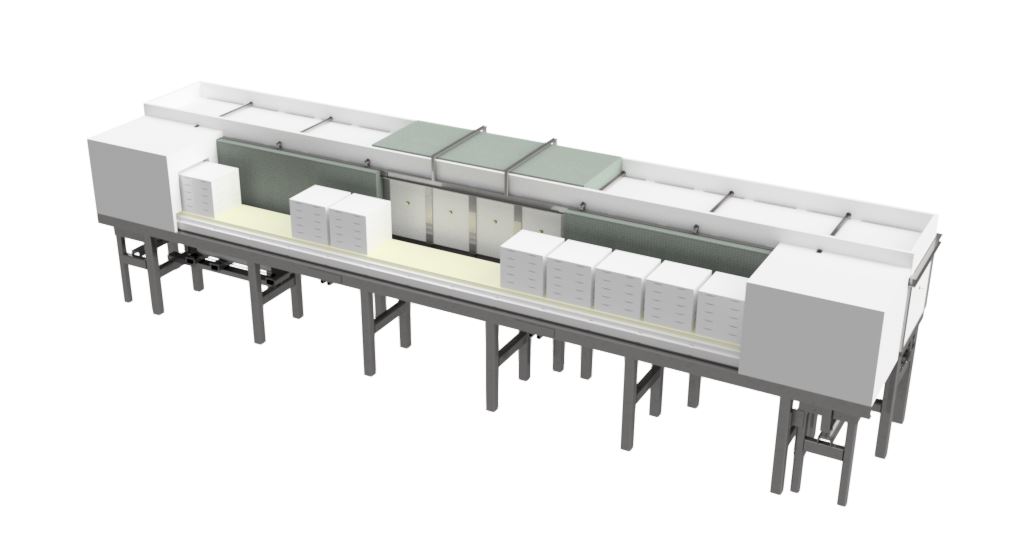

Tunnel kilns have a fundamentally different mode of operation. Tunnel kilns consist of a long tunnel which is heated to firing temperature only in the middle. Items are loaded into one end of the tunnel and then transported (typically in kiln cars) slowly to the firing zone. As objects approach the firing zone in a tunnel kiln, the temperature increases, enabling the heating rate of items to be controlled. Similarly, after items have passed through the firing zone, the temperature decreases in a controlled manner as they move towards the exit of the tunnel kiln.

Reaching lengths of up to 200m long, Tunnel kilns are often housed in dedicated buildings or rooms. Tunnel kilns are geared toward high-volume production, where their continuous operation and unique architecture offer numerous advantages in applications where throughput is a high priority.1

High-throughput

The primary advantage of tunnel kilns is that they support much higher throughput rates than intermittent kilns. While intermittent kilns must hold a (usually small) batch of products throughout an entire temperature cycle, tunnel kilns can simultaneously heat and cool large volumes of products continuously, with no ‘wasted’ time during charging or discharging.

For this reason, tunnel kilns are preferred for commodity items such as brick and tiles and high production volumes of technical ceramics, vitrified clay pipe, porcelain insulators, tableware, and sanitary ware.

Energy efficiency and emissions

As well as providing higher throughput, tunnel kilns are much more energy-efficient than their intermittent counterparts.2 This is largely because tunnel kilns actively recycle the heat given off during cooling to pre-heat products on their way into the firing zone: cold air enters the kiln through the car exit and is heated up while cooling the loads. This means tunnel kilns offer up to 50% less fuel consumption than shuttle kilns. Tunnel kilns also typically give off much lower levels of particulate matter than other kilns and can offer better levels of temperature uniformity.

Automation and maintenance

Because they require no manual charging/discharging, tunnel kilns are well-suited to integration into continuous and/or automated production lines. As well as requiring less manual supervision during operation, tunnel kilns have much lower maintenance requirements than intermittent kilns: typically, a tunnel kiln requires maintenance every one or two years.

Since they’re suited to high-volume production, tunnel kilns have a large footprint. Deltech offers a full range of custom small-scale tunnel kiln options that can be tailored to suit your specific application. Deltech tunnel kilns offer sustained operating temperatures of 1800 C and can be configured as either single or multi-zone, including pre-heat and cool-down sections. Additional options include fiberboard or ceramic lining, controlled atmosphere capability, additional length and custom-made control systems to meet your process specifications.

Interested in upgrading your current intermittent kiln system to a tunnel kiln? Get in touch with Deltech today to find out more about our tunnel kiln solutions.

References and Further Reading

Deltech is a family owned small business incorporated in 1968. Members of the Stevenson family are part of the day-to-day operations in management, sales, engineering, and production.

Address:

Deltech Inc.

1007 East 75th Avenue, Unit E

Denver, CO 80229-6442 U.S.A.

© Copyright 1998 -2024 Deltech Furnaces

PRIVACY POLICY | SITE REQUIREMENTS | SITE MAP | INFO FOR EMPLOYEES

Our ongoing accessibility effort works towards being in line with the Web Content Accessibility Guidelines (WCAG) version 2.2, levels A and AA criteria. These guidelines not only help make web content accessible to users with sensory, cognitive, and mobility disabilities but ultimately to all users, regardless of ability.

This website is just part of a meaningful change in making all State of Colorado services inclusive and accessible. We welcome comments on how to improve this website’s accessibility for users with disabilities and for requests for accommodations to any State of Colorado services.