Thermal processes generate various particulates and gases which may be harmful to technicians in the working environment. Furnace exhaust systems are used to vent these by-products from the heating chamber to the outside air. Typically, this is done continuously while the furnace is operational to maintain an optimal working atmosphere, and throughout any programmed cooling periods to maximise toxic fume prevention.

Generally, industrial furnace exhausts follow the same basic principles as any other furnace exhaust system. A chimney or a series of contiguous metal gas pipes provide a pathway for emissions to be drawn from the heating chamber via natural draft or by using a fan to induce higher efficiency circulation.

In this article, we will explore three things you should know about furnace exhaust systems.

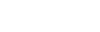

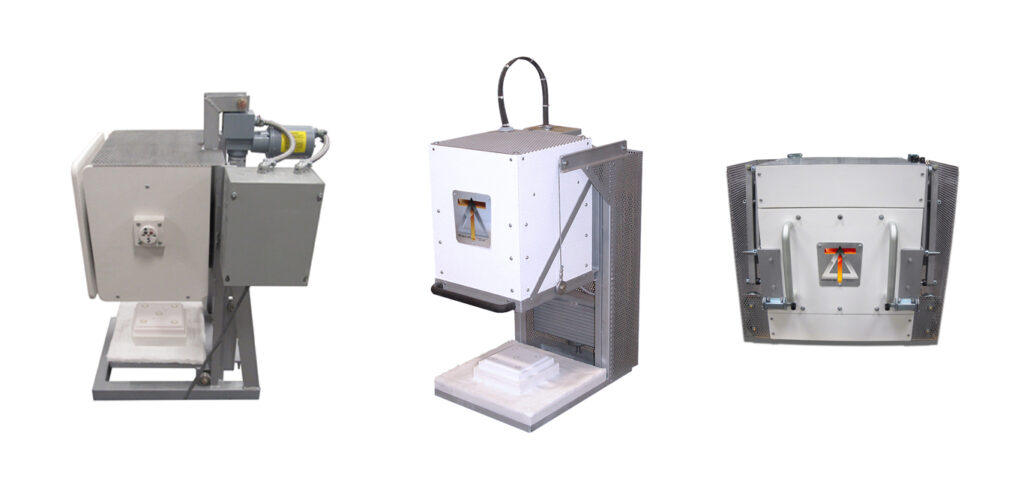

- Furnace exhaust systems come in various shapes and sizes

Heat treating equipment varies from benchtop muffle furnaces through to full-scale tunnel kilns. So, naturally, there is enormous variation in furnace exhaust systems. Most benchtop furnaces are equipped with an exhaust air outlet in the rear wall or roof, which can be connected to local ventilation directly, or be positioned beneath a fan-assisted inlet like a fume hood. These configurations enable the upstream direction of exhaust gases into the local ventilation where it is directed outside of the facility.

- Some exhaust systems treat as well as vent emissions

Just as some exhaust flues are equipped with fans to increase ventilation efficiency, others are equipped with catalytic converters which catalytically scrub exhaust fumes and break down organic components into carbon dioxide and water vapour. This can help with environmental regulations and in eliminating irritating odours. Some furnace exhaust systems are also equipped with a torch to burn-off excess flammable gases.

3. Exhaust systems can assist with process control and safety

Process control systems can be integrated into furnace exhaust systems to continuously or periodically monitor key exhaust gas parameters like composition/temperature. Variations can be fed back to central control systems where automated alarms can be triggered in the event of hazardous conditions. Additionally, custom human machine interface (HMI) systems can be developed to allow remote access and control plus event logging, so that the furnace exhaust system functions as part of a detailed feedback loop useful for quality assurance and safety management.

Custom Furnace Solutions from Deltech

Deltech Furnaces is a family-run business focussed on supplying custom furnace solutions to clients around the world. We offer a wide range of bespoke configurations complete with furnace exhaust systems that meet the unique needs of your workplace and process.